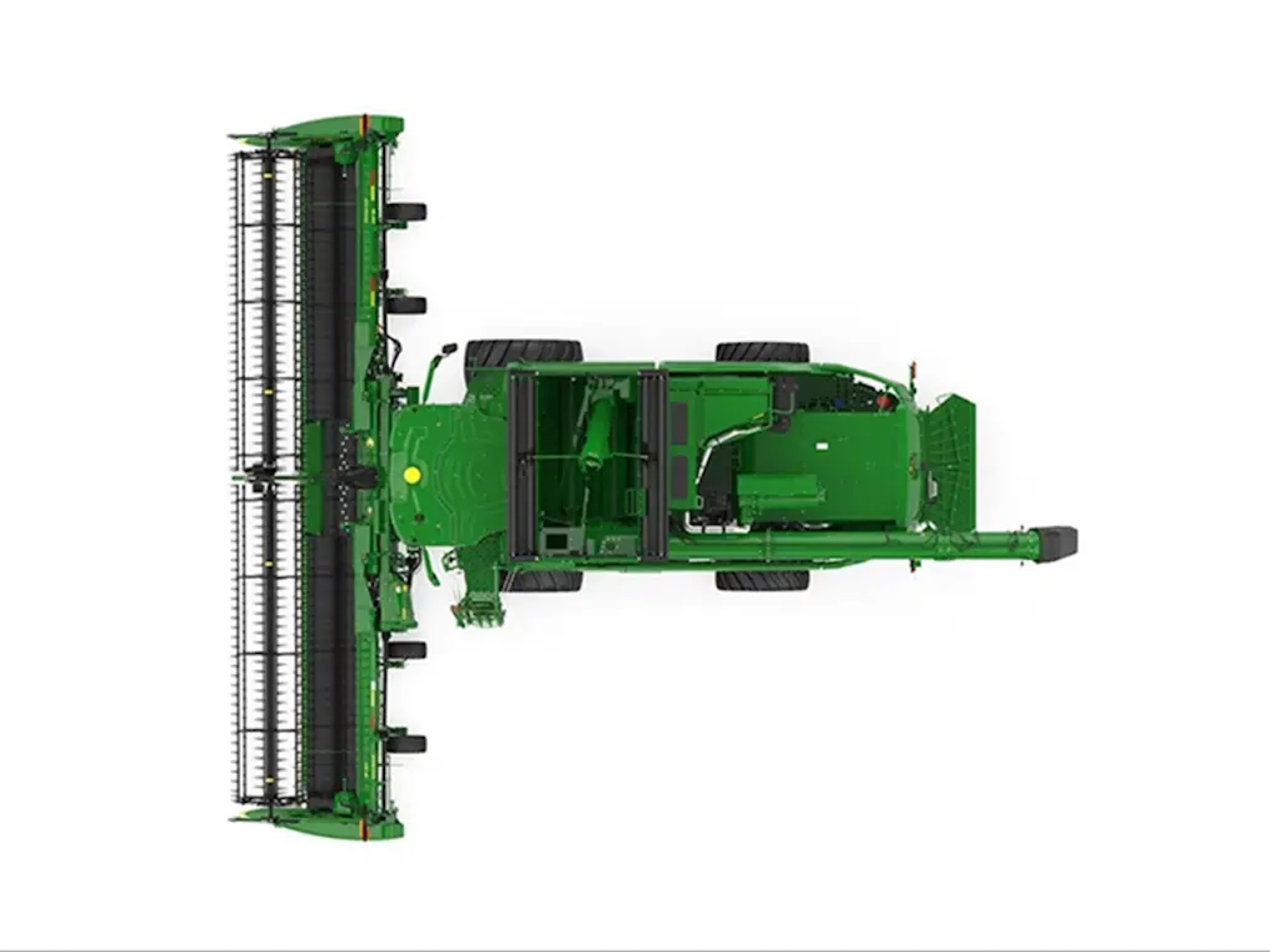

2025 John Deere T6 800

Get in Touch

Description

2025 John Deere T6 800

Features May Include:

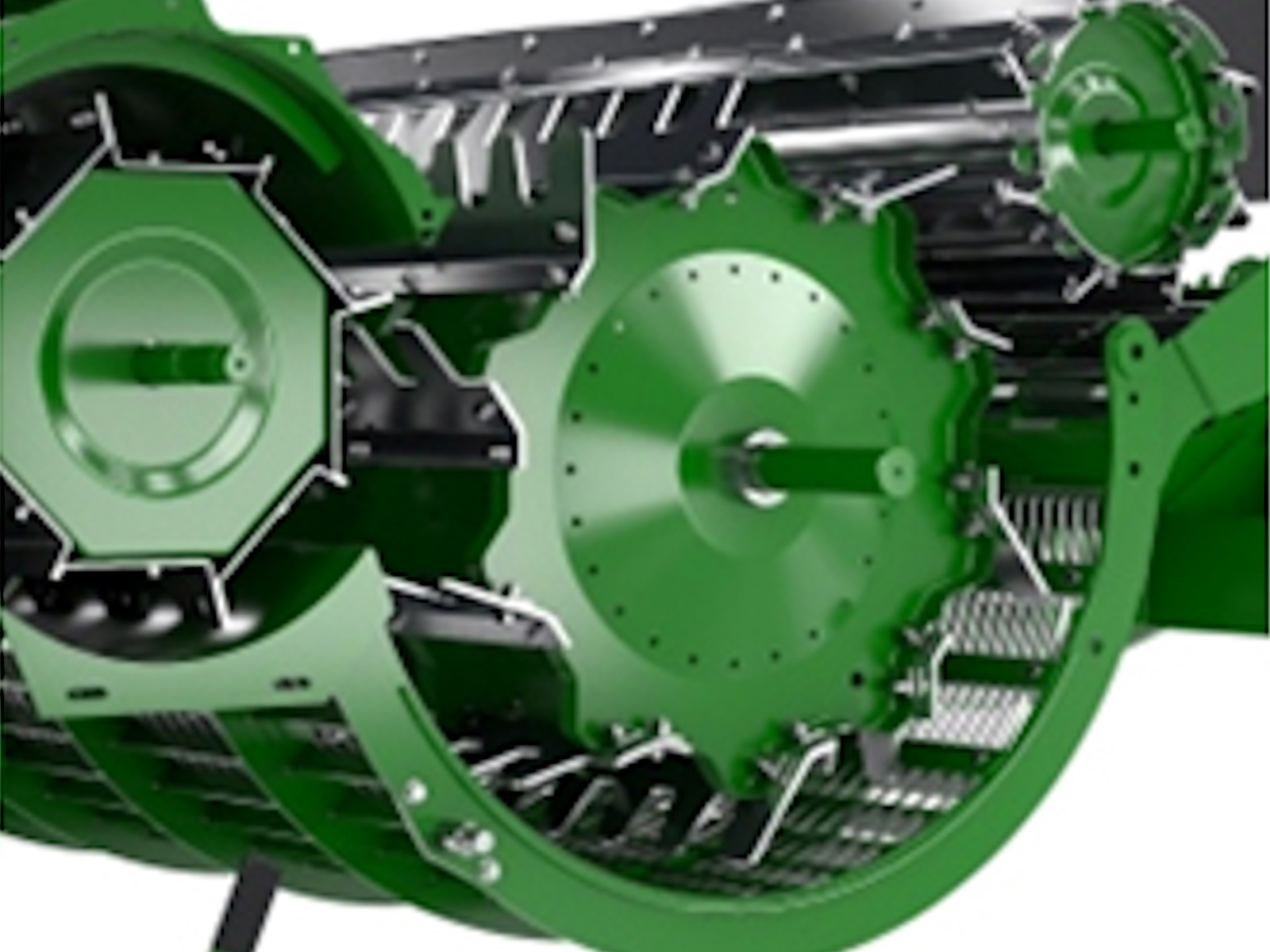

- Achieve smooth crop flow with the multi-drum threshing system

Functional components:

- Large, 660-mm (26-in.) diameter threshing cylinder with 10 rasp bars and increased concave area

- Smooth stripper roll and enlarged overshot beater

- Enlarged, 800-mm (31.5-in.) separator with high-performance separation grate

- Eight-wing, 400-mm (15.7-in.) rear beater and rear beater grate

- Seven-step straw walker design with welded or optional bolted universal and corn-cob mix (CCM) grids

- Sectional concave with quick adjustable de-awning plates

LARGE, 660-MM (26-IN.) THRESHING CYLINDER WITH 10 RASP BARS AND ENLARGED CONCAVE

The unique multi-drum threshing system ensures a consistent crop flow by moving crop above the rear beater without sharp bends or abrupt changes in direction. This guarantees excellent grain and straw quality and reduces power requirements.

- Second-largest cleaning shoe on the market to the John Deere X9 Combines

The T-Series Combine is designed for high capacity. The T670 has a total sieve and chaffer area of 6.3 m² (67.8 sq ft) according to ISO Norm 6689: 1997, which is the largest cleaning shoe following the John Deere X9 Combines.

- The Flat Tooth Comb (FTC) chaffer prevent short straw from falling through the grid as they are equipped with special noses.

- The returns are guided back to the cylinder and distributed evenly over the entire width of the threshing cylinder by an auger. The amount of material is recorded and then displayed in the cab via the electronic sensors. To visually inspect the content of the tailings returns, there is an inspection flap just outside the cab door.

- The completely redesigned fan delivers up to 740 m³ (26,133 cu ft) of air per minute and evenly distributes air over the entire width. The large air volume paired with the air flow and the large sieve area makes additional slope compensating features obsolete.

- One non-ventilated step plus two ventilated steps cascades the crop down by 41 cm (16.1 in.) to ensure effective pre-cleaning of chaff. Through intensive testing, John Deere has found the right balance between air pressure and air volume. The air pressure is used to separate the grain and the air volume allows for material to be carried away. This provides the perfect pre-separation effect and evenly divides the material between the front and rear part of the chaffer.

- The heavy-duty conveyor augers ensure active crop flow on slopes and under tough harvest conditions, meaning the cleaning shoe can be optimally loaded even in damp or sticky conditions.

- The total sieve and chaffer, with its considerably enlarged surface up to 6.3 m² (67.8 sq ft), offers high cleaning performance even under tough threshing conditions.

- Increase threshing capabilities with the quick-engage booster bar

The quick-engage booster bar is adjustable from the outside via the stone trap with a 24-mm (0.95-in.) wrench. It has two positions. In the engaged position, the concave entrance features a profiled rasp bar. In the disengaged position, the concave entrance features a smooth transition plate. Adjustment can be completed easily within minutes.

Material flow coming from the feeder house passing the booster bar is slowed down; this increases the threshing efficiency. The booster bar does not have a negative influence on the crop flow or the grain quality. The booster bar increases threshing efficiency in hard-to-thresh crops without closing the de-awning plates, allowing maximum separation at the concave area.

- Save time unloading on the go with a peak unload rate of 125-L/s (3.55 bu/sec) and Machine Sync

The extra-fast unloading system provides a peak rate of 125 L/s (3.55 bu/sec) according to ISO 5687:1999 Norm. Compared to the John Deere S770 Combine’s unload rate of 116.3 L/s (3.3 bu/sec), the T670 has a faster unload rate that is also reflected in time saved when unloading on the headland. The extra-fast unloading system comes as the base option on the T670 Combine. Fast unloading on the go allows the operator to concentrate more on the crop by reducing unloading time.

The higher unload rate is achieved by the grain tank cross augers, an increased discharge housing including vertical auger, larger sprockets and chain, and an overall higher speed of the unloading system.

On the headland, the operator can reduce the rate by putting the machine at mid-idle or low idle; this allows for more precision, especially when the trailer is nearly full.

- Enhanced extra fine cut residue system for high quality chopping and residue distribution

The improved extra fine cut straw chopper delivers excellent chopping quality and best-in-class residue distribution of chopped material in the field with a cutting width up to 10.7 m (35 ft) and 108 knives.

The extra fine cut chopper comes standard with serrated chopper knives, which ensure superior splicing of the straw and improved straw rotting process. This chopper is highly recommended for producers with no tillage or minimum tillage operations.

The optional dual-speed chopper drive provides flexibility to match all crops and conditions.

Info

Industry

Agriculture

Make

John Deere

Model

T6 800

Trim

Base

Year

2025

MSRP

N/A

Category

Combine

Subcategory

General

Specs

Engine Type

John Deere PowerTech PSS engine 548 cu in.

Power/Horsepower

rated: 392 hp

Fuel Capacity

211 gal.

Length

73 in.